Past Fundamentals: DTF Printing Techniques for Exceptional Fabric Creations

Past Fundamentals: DTF Printing Techniques for Exceptional Fabric Creations

Blog Article

The Future of Style: Exploring DTF Printing Modern Technology in the Textile Sector

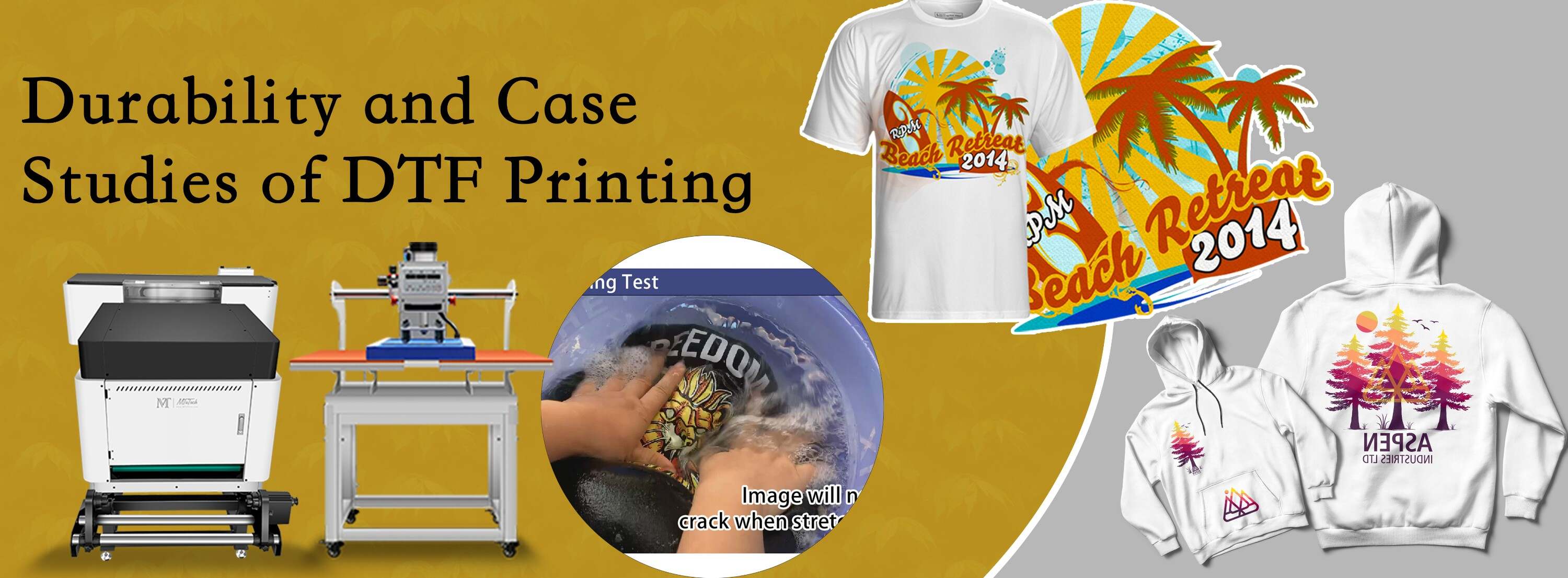

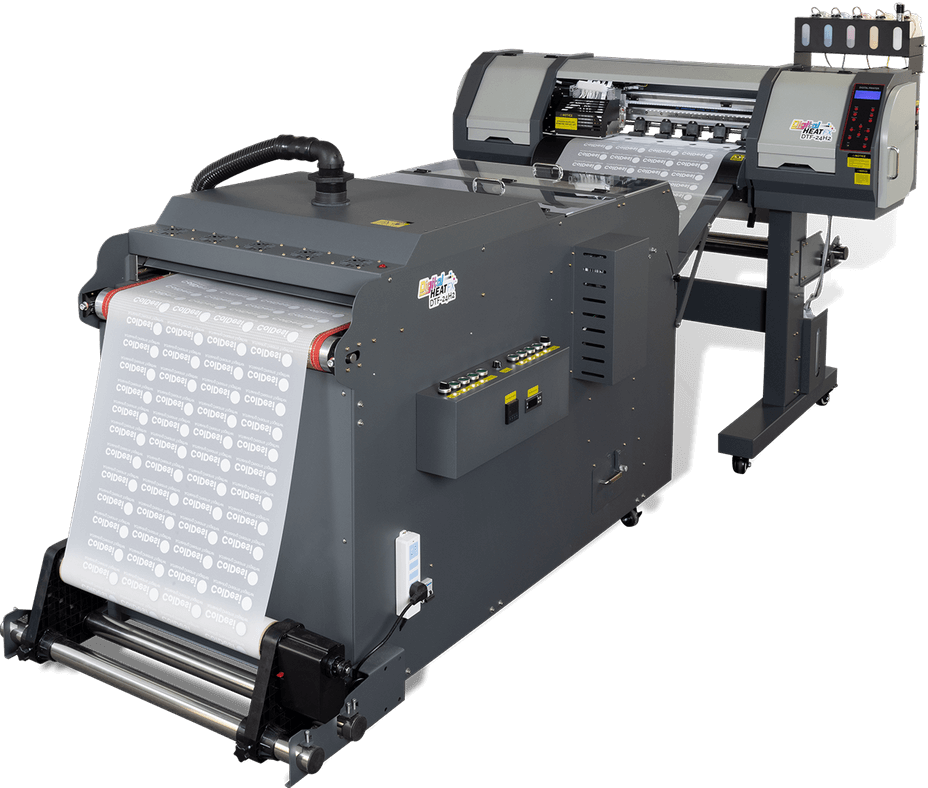

Amongst these developments, Straight to Movie (DTF) printing modern technology has emerged as a promising competitor, using unique capabilities and chances for developers and makers alike. This sophisticated printing method has sparked rate of interest due to its prospective to change typical textile printing processes.

Evolution of Fabric Printing

From the ancient people utilizing strategies like block printing to the electronic change of today, fabric printing has continually pressed boundaries. As the craft spread to various other components of the world, brand-new methods such as display printing and roller printing emerged during the Industrial Transformation, transforming the fabric market.

The intro of digital fabric printing in the late 20th century marked a significant change towards even more sustainable and functional printing techniques. The evolution of textile printing showcases an abundant history of imagination, resourcefulness, and technological progression in the world of style and style.

Advantages of DTF Technology

With the development of fabric printing methods from old methods like block printing to contemporary innovations such as digital printing, the intro of Direct-to-Fabric (DTF) technology has significantly enhanced the performance and sustainability of fabric printing processes. One of the main advantages of DTF modern technology is its capacity to directly publish designs onto fabric without the requirement for transfer documents, which reduces waste and simplifies the production process. Furthermore, DTF printing enables greater color vibrancy and detail accuracy contrasted to traditional techniques, enabling textile manufacturers to produce top quality and elaborate designs easily.

Furthermore, DTF innovation is understood for its adaptability, as it can be made use of on numerous sorts of textiles, consisting of all-natural fibers like cotton, silk, and wool, as well as synthetic products such as polyester and nylon (DTF Printing). This adaptability opens up a vast array of possibilities for suppliers and developers to explore different textures and materials, leading to even more ingenious and unique items in the apparel industry. On the whole, the execution of DTF innovation represents a significant advancement in fabric printing, using many advantages that add to the future sustainability and creativity of the market

Sustainability in Fashion Manufacturing

Highlighting environmentally friendly methods is paramount in modern style production, straightening with the expanding customer need for lasting products. Over the last few years, the garment industry has encountered enhancing analysis due to its substantial environmental effect, consisting of excessive water use, chemical air pollution, and textile waste. As a feedback, numerous style brand names are now integrating lasting practices into their manufacturing procedures to reduce injury to the environment.

Sustainability in style manufacturing encompasses different facets, such as using organic and recycled products, minimizing power consumption, applying ethical labor methods, and promoting transparency throughout the supply chain. Additionally, innovations in innovation, like DTF printing, deal opportunities to even more boost sustainability in textile manufacturing. This modern technology allows precise printing on textiles, decreasing ink waste and water use compared to conventional printing approaches.

Design Freedom and Personalization

Furthermore, DTF printing promotes modification on a scale previously unattainable, allowing for their explanation individualized garments and unique pieces customized to individual choices. In general, DTF printing innovation revolutionizes the style landscape in the textile market, supplying unlimited opportunities for creative expression and individualized fashion.

Effect on Supply Chain & Market Trends

DTF printing innovation in the textile industry is improving supply chain characteristics and affecting market patterns through its efficiency and modification capacities. By allowing on-demand printing and getting rid of the need for huge supplies, DTF innovation improves the supply chain process.

Furthermore, the customization capacity of DTF printing technology is reinventing the market trends in the fabric her explanation market. As a result, DTF innovation is driving a change towards even more ingenious and customer-centric approaches within the textile sector, shaping the future of fashion.

Final Thought

Finally, DTF printing innovation is changing the textile market by supplying various advantages such as layout sustainability, customization, and flexibility. This cutting-edge technology is improving the future of style production, impacting supply chains, and driving market patterns in the direction of more eco-friendly and efficient practices. As the market continues to progress, DTF printing will certainly play a critical role in shaping the method fabrics are generated and eaten in the years to come.

From the ancient people making use of techniques like block printing to the digital revolution of today, textile printing has continually image source pressed borders. As the craft spread to various other components of the globe, brand-new techniques such as screen printing and roller printing emerged during the Industrial Revolution, transforming the textile market.

The intro of digital textile printing in the late 20th century noted a substantial change towards more functional and sustainable printing techniques.With the evolution of fabric printing strategies from old methods like block printing to modern technologies such as electronic printing, the introduction of Direct-to-Fabric (DTF) technology has actually substantially improved the efficiency and sustainability of fabric printing processes (DTF Printing).In response to the essential shift in the direction of sustainability in style production, the fostering of ingenious technologies like DTF printing not just addresses environmental problems however also opens up methods for unequaled style freedom and modification in the textile sector

Report this page